To optimize performance, begin at the pulverizers

A systematic, performancedriven maintenance program for optimizing combustion can achieve great results. The challenge for an OM staff is deciding which proven strategy and tactics for reducing ...

WhatsApp)

WhatsApp)

A systematic, performancedriven maintenance program for optimizing combustion can achieve great results. The challenge for an OM staff is deciding which proven strategy and tactics for reducing ...

Performance Driven Maintenance of Coal Pulverizers. Overhauling a Pulverizer for Best Performance Typical Triggers for a Pulverizer Overhaul: • Prescribed maintenance interval (hours, tons throughput, months. • Noise, Coal Rejects excessive, Capacity Short. • Repair damaged or worn parts, grinding elements classifier components, etc.

Optimized coal pulverizer performance is a prerequisite for ensuring the best furnace combustion efficacy. Here are some solutions for overcoming commonly identified combustion problems. Coal ...

Coal Pulverizer Maintenance Improves Boiler Combustion. Dec 1, 2015 Optimized coal pulverizer performance is a prerequisite for ensuring the best furnace combustion efficacy. Here are some solutions for overcoming commonly identified combustion problems. Coal pulverizers are the heart of a pulverized coalfueled boiler.

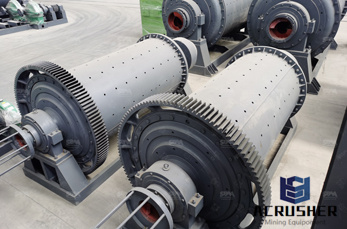

Ball and tube mill pulverizer marinetaxiscoza. Performance Driven Maintenance of Coal Pulverizers Storm Boiler Reliability minimize tube Fineness Testing should be used as a trigger for maintenance on mills This was a ball tube mill and the issues started Read More

Performance Driven Maintenance of Coal Pulverizers Our Point: If Coal Fineness is not representatively sampled, then Pulverizer Grinding Performance is not known? Fineness Testing should be used as a trigger for maintenance on mills. Get price

Performance Driven Maintenance of Coal Pulverizers. Performance Driven Maintenance of Coal Pulverizers Importance of Mill Performance Testing Data and Case Studies Prepared by: Jesse Parnell ... Coal Pulverizers are the Heart of a Pulverized Coal Fueled Boiler! ... Pulverizer performance testing provides insight to operation and performance.

Grinding Action is carried out by a series of hinged or fixed hammers revolving in an. Improving Coal Pulverizer Performance and Reliability. Get Price Performance Driven Maintenance of Coal Pulverizers Storm ...

Wikipedia Mps 89 Pulverizer Maintenance. Performance driven maintenance of coal pulverizers without performance driven maintenance pulverizer performance could look like thishis was a ball tube mill and the issues started with reject lines were not working properly, classifier blades out of synchronization, 3 on crusher dryer clearances.

Home → Products → Coal Power → Tire Pulverizer Wear Parts We cast a variety of replacement parts for MPS 89, MPS 89G, and MPS 89R coal pulverizers. Columbia Steel wear parts for BW MPS coal pulverizers are an example of our ability to produce superior quality parts that offer excellent fit, top performance and exceptionally long life.

Coal Pulverizer at Best Price in India. Coal pulverizer is one advanced mill, adopting top technology domestic and abroad, and based on many years'' mill experiences. it can crush, dry, grind, and classify the materials. coal pulverizer can be . Learn More; Pulverizer Capacity is not simply "tons throughput per hour!" pulverizer capacity.

maintenance manual of coal pulverizer pdf Maintenance Manual Of Coal Pulverizer Pdf Reserve Maintenance Manual IOMM_IMAS / Ver mill Loesche Coal Mill Operation And Maintenance Pdf Crusher. More Products; for mills PULVERIZERS Wabash Power. for mills PULVERIZERS, CE RAYMOND BOWL MILL COAL . Learn More

Improving Coal Pulverizer Performance and Reliability. races may rotate against a ball or roll (in a RingRoll Mill the rolls may rotate while the ring is stationary). RingRoll (BowlMill) and BallRace Mills comprise the majority of coal pulverizers currently in service at power generating facilities.

Performance Driven Maintenance of Coal Pulverizers. Overhauling a Pulverizer for Best Performance Typical Triggers for a Pulverizer Overhaul: • Prescribed maintenance interval (hours, tons throughput, months. • Noise, Coal Rejects excessive, Capacity Short. • Repair damaged or worn parts, grinding elements classifier components, etc.

Performance Driven Maintenance of Coal Pulverizers. Overhauling a Pulverizer for Best Performance Typical Triggers for a Pulverizer Overhaul: • Prescribed maintenance interval (hours, tons throughput, months. • Noise, Coal Rejects excessive, Capacity Short. • Repair damaged or worn parts, grinding elements classifier components, etc.

Performance Driven Maintenance of Coal Pulverizers Storm ... Our Point: If Coal Fineness is not representatively sampled, then Pulverizer Grinding Performance is not known? Fineness Testing should be used as a trigger for maintenance on mills. ... Pre and Post Outage Testing Results. As shown here...

Performance Driven Maintenance of Coal Pulverizers Storm ... classifier components, etc. • Prove by Testing, "Best" Pulverizer Performance is acceptable. Coal Fineness and Coal Distribution.

performance with Storm pulverizer components How to preserve furnace performance by applying Storm performance driven maintenance • • • • • • Storm Technologies, Inc. PO Box 429 Albemarle, NC 28002 Phone: (704) Fax: (704) America still depends on coal to keep our lights on. People like you and me ...

Coal Pulverizer''''s are used to pulverize the coal into a fine powder of size around ... Pulverizing the coal to a fine powder is an important function in the operation of a power plant. ... The hot air under pressure carries this ground coal upwards. ... changes as they wear out during pulverizing, increasing the maintenance cost.

Performance Driven Maintenance of Coal Pulverizers. Without performance driven maintenance pulverizer performance could look like this.. This was a ball tube mill and the issues started with reject lines were not working properly, classifier blades out of synchronization, +3" on crusher dryer clearances.

Performance Driven Maintenance of Coal Pulverizers Know More. Performance Driven Maintenance of Coal Pulverizers, Coal Pulverizers are the Heart of a, Fineness Testing should be used as a trigger for maintenance on mills...

Coal Pulverizer Maintenance Improves Boiler Combustion · Optimized coal pulverizer performance is a prerequisite for ensuring the best furnace combustion efficacy. Here are some solutions for overcoming commonly identified combustion problems. Coal pulverizers are the heart of a pulverized coalfueled boiler. Often, the root causes of nonoptimized

Performance Driven Maintenance of Coal Pulverizers. Performance Driven Maintenance Provides A Path to Achieve Results Improved 50 mesh by adjusting classifier blad By conducting periodic Isokinetic coal sampling pulverizer performance can be tracked so that maintenance decisions are based on the truly, [24/7 online]

Performance Driven Maintenance of Coal Pulverizers Importance of Mill Performance Testing: Download: 6/14/2012: ONE MORE TIME: FIRST APPLY THE FUNDAMENTALS! RMEL Plant Management Conference: Download: 6/28/2011: Efficiency Improvements to the Existing CoalFired Fleet ACC Fuel Flex 2011: Download: 6/16/2011: Why Coal is Important for America ...

WhatsApp)

WhatsApp)