WhatsApp)

WhatsApp)

Concrete. Concrete is a composite of aggregate (such as sand or gravel), cement, and water. The cement makes up from 10 15% of the total mass of concrete; the exact proportions vary depending on the type of concrete being made. Aggregate makes up more than 60% of a concrete mix — and up to 80% in some cases.

Mar 19, 2011· Paving with Soil Cement (1962) Duration: 28:10. ... How to Hand Mix Concrete With Rock,Sand,Cement and Water! Custom mixtures Finishes! ... SemiMechanized Adobe Brick Making .

SoilCement Ratio and Curing Conditions as the Factors of SoilConcrete Strength Article (PDF Available) in Key Engineering Materials 730:358363 · February 2017 with 1,826 Reads

Bricks for Africa are one of the South Africa''s leading brick and building material merchants, and the biggest independent Corobrik distributor.

Oct 21, 2018· BUILD BUILDINGS STABILIZED SOIL CEMENT BRICKS, RED SOIL CLAY BRICK HOUSE GiantLin Brick Machinery Factory ... semi automatic brick machine, concrete movable block machine, clay interlocking ...

Exciting opportunity for anyone looking to try their hand at being an entrepeneur!A profitable and sustainable business venture in the current Machines up for x Big block making machine1 x Standard brick making machineExtra''s included concrete mixer, pigment,stackin g boardsCan be customized to create specific moulds.

Brick making machine for sale in south africa has reasonable price, it can be used to make all kinds of bricks, such as, interlocking bricks, hollow blocks, solid block and stand block, color blocks, etc.

Make Your Own Bricks from Soil DIY MOTHER EARTH NEWS

Mar 07, 2009· you mix concrete with sand or gravel (which includes small rocks)for strength. with dirt (soil) there is organic matter that will rot and shrink making the concrete brittle so it chips and falls apart. it also won''t hold up with winter''s frost. That is a very good .

2. The soil cement mixture must be used up within one hour. Checking the moisture of the mixture . Squeeze the soil cement mixture into a ball . Drop the ball from waist high . As what shows in the photo. Second one is the best to make ECO bricks and blocks. ECO bricks .

To know if the soil near your concrete is affecting planting soil, perform a soil sample that checks for pH. Acid loving plants prefer a pH of to, ornamental plants and lawn grasses like a ...

1/2″ Portland Cement 3 1/2″ Dirt Water. Tools Needed: Tamper (10″ or larger) Rototiller (Rotor Tiller) Directions: Pour approximately 1/2″ of cement on slab/porch area. Roto Till down 4″ to mix while spraying with water (moist not sloshy). After cement soil are .

More water, cement or sand can be added if the mixture is too wet or dry. Below is an example of a sand to cement mix ratio recommendation from a cement manufacturer. Concrete 1 part cement, 2 parts concreting sand and 3 parts 20 millimeter aggregate. Mortar 1 part cement, 4 to 5 parts building sand.

Adding water to this mix activates the cement so that it hardens, or cures, just as with concrete. Mortar is not as strong as concrete and typically is not used as a sole building material. Rather, is it the "glue" that holds together bricks, concrete block, stone, and other masonry materials.

Assume the mix ratio required is 1:2:3 (one part cement to two parts sand to three parts stone – six parts in total. (all mixes are printed on a pocket of cement). Now divide the six parts into 4500ml: 750ml x 1 = 750ml Cement 750ml x 2 = 1 500ml Sand 750ml x 3 = 2 250ml Stone

Add water to the soil and clay mixture, slowly and gradually. The mixture should hold a shape, but be soft enough to fill the mold. Experiment with one brick until you get the right consistency. For example, if you want to make 10 bricks, you''ll need 3/4 gallon of water.

Soil Brick Making Machine From South Africa. soil drying equipment south africa Posted at: Find detailed product information for SY120 hydraulic soil cement brick making machine south africa .

Make Your Own Bricks from Soil How to make bricks to build a home: including the five basics of blockmaking, soil composition, and mixing the bricks. By Folsom

Interlocking Bricks (CSEB) are made by mixing and compressing Sand, Soil and Cement in a machine. It can also be made from stonedust and cement. The bricks are then stacked and cured for 21 days – the cement sets and bonds with the sand stabilizing the brick. Earthquake resistant.

Find brick making machine in South Africa! View Gumtree Free Online Classified Ads for brick making machine and more in South Africa. ... Here is a Concrete Block layer with mold for M140 blocks for sale. Just in time for the full return of the construction industry in 2020. Comes with 200 litre concrete .

Aggregates and cement should be ordered in good time. Stocks should be sufficient to prevent stoppages due to lack of material. As a rough guide, using aggregate cement ratio of 8:1 by loose volume, three and a half bags of cement and a cubic metre of aggregate will be enough to make about 400 standard bricks.

A DIY Brick machine, making standard stock bricks from: R2 600; Output per drop: 6; Production per day: 3 000; 3. Build for less using the Hydraform system. What makes Hydraform blocks different from a regular brick is that they are composed of soil and just 510% cement is needed in the mix, significantly reducing the cost per square metre.

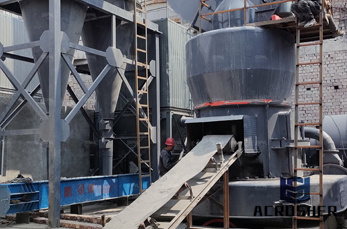

As a professional construction machinery supplier, Aimix can provide concrete mixing plant, asphalt plant, dry mix mortar plant, stable soil mixing plant, concrete pump machine, brick machine, concrete mixer, screw conveyor, wheel loader, cement silo and other machinery. Contact us to get more details or the best price.

WhatsApp)

WhatsApp)