(PDF) Evaluation of lead zinc ore tailings by flotation

PDF | Evaluation of tailings from processing plants is always an important issue. LeadZinc ore tailings containing % Zn, % Pb, g/t Au and 74 g/t Ag was subject to this study.

WhatsApp)

WhatsApp)

PDF | Evaluation of tailings from processing plants is always an important issue. LeadZinc ore tailings containing % Zn, % Pb, g/t Au and 74 g/t Ag was subject to this study.

Aug 13, 2018· New Century Resources has started flotation and production of zinc concentrate at the Century mine processing plant in Queensland. The company, which launched hydraulic mining .

The LaRonde mine is also the site for the Lapa mine ore processing plant (1,500 tonnes per day), which was commissioned in the second quarter of 2009. The ore requires a series of grinding, copper/lead flotation and separation, zinc flotation and zinc tails precious metals .

Galena has good floatability. In most leadzinc mines, zinc is higher than lead. Most of the leadzinc sulfide mine uses preferential flotation technology, "floating lead and zincsuppressing", which is often reasonable both technically and economically. 2 Leadzinc oxide ore

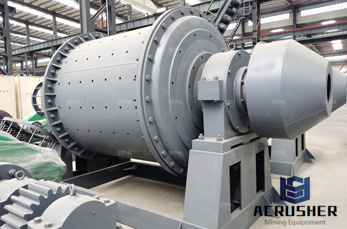

Flotation is the most widely used beneficiation method for fine materials, and almost all ores can be separated by flotation. Another important application is to reduce ash in fine coal and to remove fine pyrite from coal. The flotation machine is mechanical equipment for realizing the froth flotation process and separating target minerals from ore.

Lead and Zinc Ore beneficiation Due to low zinc content, runofmine zincbearing ores must be concentrated before smelting and refining. Beneficiation, which usually occurs at the mine, consists of crushing, grinding, and flotation to produce concentrates of 50 to 60 percent zinc.

This leadzinc polymetallic mine was located in the "threeriver" High Mountain and canyon area of eastern Tibet and the elevation was from 3200 to 4040m. The climate of this area was continental plateau cold temperate zone semiarid monsoon. The characteristic of the mine was mainly mineral assemblages of Pb, Sb and Zn.

Zinc is a bluishwhite metallic chemical element that is ductile in its pure form but in the commercial form it is brittle at room temperature and becomes ductile on slight heating. It occurs amply in minerals and is considered an essential micro nutrient for both plants and animals.

Compared to tin mining, the history of zinc mining is relatively short. In the 18th century, it was discovered that sphalerite, or zinc sulfide, could be smelted into brass, resulting in the first patented techniques. Since then, the zinc industry has progressed to the current zinc mining process and production methods used today.

Sep 26, 2019· The June 27, 2019 PEA highlights strong potential economics for a low cost, relatively simple, open pit zinc mine and flotation plant operating, producing, and selling zinc concentrate for 12 ...

Many installations of the Visual Sampler have proved this unit to be a moneysaving necessity in any flotation plant. Pb and Zn Concentrate Filtration. ... lead ore, pb, silver, silver flotation, zinc, zinc mining, zinc ore, zn | Comments Off on Silver Lead Zinc Ore Processing Method using Flotation.

The gold CIL process is mainly used in the oxide ore which has low grade of silver, its more economize and has more benefit . ... gold rock crusher, cost of gold refinery, gold mining plant, mining equipment co ltd, smelting gold ore, mining for cobalt, cyanide in mining, ball milling machine, gold centrifuge separator, mining heap leaching ...

Sep 26, 2019· The June 27, 2019 PEA highlights strong potential economics for a low cost, relatively simple, open pit zinc mine and flotation plant operating, producing, and selling zinc concentrate for 12 ...

The nonmagnetic tails from the separation process, which contain essentially all of the copper and zinc minerals, would feed a standard flotation process plant with design capacity of 6,500 tonnes per day to accommodate variations in the proportion of magnetite in run of mine material. Feed grade to the flotation plant is expected to be in the ...

domestic leadzinc mining industry and is one of a series of profiles of major mining sectors. Additional profiles describe copper mining, gold mining, iron mining, and several industrial mineral sectors, as presented in the current literature. EPA prepared these profiles to enhance and update its understanding of the mining

Dec 20, 2018· SF Flotation Plant is widely used for roughing, concentrating and counterflotation of nonferrous metal that includes gold, copper, lead, zinc, nickel and molybdenum, ferrous metal and nonmetallic mineral.. Working Principle of the flotation plant. The impeller is driven by Vbelts, which can bring the centrifugal effect to form the negative pressure.

flotation plant for sale for copper. copper ore flotation plant for sale offers 268 copper leaching products About 36% of these are other mining machines, 2% are geomembranes, and 1% are geocells A wide variety of copper leaching options are available to you, such as free sampl Get Price Copper Cathode Plant.

model predictive control based approach has been developed and tested on a zinc flotation circuit in Sweden. The basic idea is to use air flows and chemicals to control the concentrate in the product and in the tailing. The activities in the project covered modeling, design, implementation, and tests at a .

Jun 04, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

offers 20,101 zinc mining plant products. About 2% of these are mineral separator, 1% are refrigeration heat exchange parts, and 1% are water treatment. A wide variety of zinc mining plant options are available to you, such as gravity separator, ball, and filling machine.

Aug 25, 2016· Flotation process of Leadzinc Beneficiation Plant in Tibet, Xinhai La Norma lead zinc mine, located in Kare Town, Chamdo County, Tibet Autonomous Region, is a 600 thousand t/a plant EPC project ...

Sep 16, 2018· The flotation tailing from the lead section passes to a lifting conditioning tank represent the feed to the zinc flotation section. The combined products flow to a zinc conditioning tank where soda ash, sodium silicate and an organic colloid are a...

Zinc processing Zinc processing Ores: Zinc ores are widely distributed throughout the world, although more than 40 percent of the world''s output originates in North America and Australia. The common zinccontaining minerals are the zinc sulfide known as zinc blende or sphalerite (ZnS), a ferrous form of zinc blende known as marmatite [(ZnFe)S], and a zinc carbonate known as calamine or ...

Flotation process maximizes the enrichment of gold into sulfide minerals The tailings can be directly discharged Flotation in gold mine has low beneficiation cost more solutions Our Service copper lead zinc ore processing plant; mining ore copper processing plant machine sold to all over the world; low pri circular vibrating screen machine .

WhatsApp)

WhatsApp)