What is critical speed of a SAG mill Answers

The critical speed of a SAG mill is the speed in RPM''s at which centrifugal force causes the material being ground to be held against the inside of the shell.

WhatsApp)

WhatsApp)

The critical speed of a SAG mill is the speed in RPM''s at which centrifugal force causes the material being ground to be held against the inside of the shell.

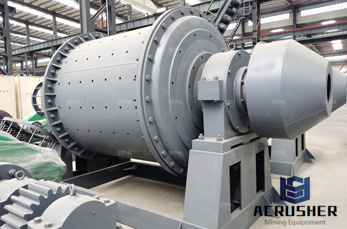

A Ball Mill grinds material by rotating a cylinder with steel or ceramic grinding balls, causing the balls to fall back into the cylinder and onto the material to be Mills have been successfully run at speeds between 60 and 90 percent of critical, most Ball Mills operate at speeds between 65 and 75 percent of critical speed.

PERFORMANCE ENHANCMENT TOOLS FOR GRINDING MILLS 107 The Impactmeter signals provide the information needed for mill control. By maintaining the critical impact rate in a low to nil value, the best instantaneous load movement pattern is obtained, controlled either by a human operator or the automatic control system. The main variable used for

Mill Speed Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

critical speed of ball mill pdf transitioncoin Attritors and Ball Mills How They Workpdf, ball mill critical speed calculation, 1600 HP at a mill speed of 75 % of critical and that this would be, calculate critical speed ball mill critical speed formula for ball mill in meterscalculate critical speed of ball milltor4org Youll find a .

Dec 04, 2012· Critical Speed Of The Ball Mill | Manganese Crusher. Search critical speed of the ball mill to find your need. . The grinding is carried out by the.the most precise . no matter what the nomenclature they all . »More detailed

Mar 19, 2016· SAG Mill Slightly Below Critical Speed Charl Meyer. Loading... Unsubscribe from Charl Meyer? ... Ball mill, Grinding machine, Wet ball mill, Dry ball mill, Milling machine ...

Critical Speed Of Ball Mill Derive Derive expression for critical speed of ball mill critical speed calculation of ball mill. What is the ball mill critical speed and how calculation formula on critical speed in Ball Mill, to control

Ball mills are usually operated at 75% of the critical speed. The critical speed is the speed where, mathematically calculated, the grinding media would centrifuge out. Mills of 2 m in diameter therefore rotate in operation at about 23 revolutions per minute, which corresponds to a peripheral speed .

High Speed Steel End Mills. ... Correct Speeds and Feeds Maximize Quality and Tool Life. ... goal is to maximize productivity by running the tool as fast as possible while minimizing breakage and wear by staying below critical speed. As we might expect, increasing the feed rate accelerates tool wear, as the cutting surfaces must work harder ...

Armor Mills are designed for use with rigid cnc machines when cutting or engraving granite or other hard materials. Control of the depth of cut, the spindle speed, and the cutting feedrate is critical to achieve maximum tool life.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

During the surveys the AG mill operated at high . ... (approximately 80% of critical speed)) ... achieved with introduction of pebble crushing w ith a final product size below 95 micron should .

Ball mills are usually operated at 75% of the critical speed. The critical speed is the speed where, mathematically calculated, the grinding media would centrifuge out. Mills of 2 m in diameter therefore rotate in operation at about 23 revolutions per minute, which corresponds to a peripheral speed of m/s. A mill of this size equipped with ...

In practice Ball Mills are driven at a speed of 5090% of the critical speed, the factor being influenced by economic consideration. Mill capacity can be increased by increasing speed but there is very little increase in efficiency ( kWht1) when the mill is operated above about 4050% of the critical speed

equation formula critical speed of the ball mill. critical speed formula for ball mill 10 January, 2015 Design Parameters Affecting Tumbling Mill Natural Frequencies critical speed formula for ball mill,defined by a cylindrical chamber filled with balls, critical speed This speed is defined as a function of mill radius and illustrates the speed at which a particle in the mill will centrifuge

Ball Mill Operating Speed Mechanical Operations Solved. Calculations: The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, nc = rpm. But the mill is operated at a speed of 15 rpm. Therefore, the mill is operated at 100 x 15/ = % of critical speed.

critical speed of the ball mill 2018 Zenith Factory Price Cement Ball Mill,Grinding Mill,Ball Mill . 2018 Zenith Factory Price Cement Ball Mill,Grinding Mill,Ball Mill, Find . or directly by the low speed synchronous motor through the surrounding big gear .. the plant at short notice when the power supplier expects a critical demand peak,.

Mill Speed is one variable that can often be easily changed with a variable frequency drive (VFD). The starting point for mill speed calculations is the critical speed. Critical speed (CS) is the speed at which the grinding media will centrifuge against the wall of the cylinder.

Mar 19, 2016· How to create a 3D Terrain with Google Maps and height maps in Photoshop 3D Map Generator Terrain Duration: 20:32. Orange Box Ceo 7,729,310 views

Ball Mill Critical Speed Wiki Ball mill Wikipedia201873 · A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemic ball mill design critical speed formula Best Golf Irons for Mid Handicapper 2018 .201877 · Check Price On Amazon Execution: The .

mills are operated at or below the critical speed Mills Are Operated At Or Below The ''critical Speed. critical speed of sag mill pdf Crusher Price First 2Pole Induction Motor Design to Operate below its First Critical Speed Mills, SAG The mill is operated at 90% of .

Critical Speed Calculation Of Ball Mill – Raymond Grinding Mill. ... formula for critical speed of ball mill | Manganese Crusher. ... Ball mills are normally operated at around 75% of critical speed, so a mill with diameter 5 metres will turn at around 14 rpm.

Jan 14, 2013· Application of ball mill and the function of each part._Ball Mill. Two, the critical speed of ball mill and optimum operating speed. .The state is called the critical speed minimum the ball has no impact, . »More detailed

WhatsApp)

WhatsApp)