RAW MILL SILO |authorSTREAM

RAW MILL SILO authorSTREAM Presentation. Presentations (PPT, KEY, PDF) ...

WhatsApp)

WhatsApp)

RAW MILL SILO authorSTREAM Presentation. Presentations (PPT, KEY, PDF) ...

Crusher operation raw mill operation rotary kiln operation cement mill operation vertical cement mill clinker quality cement quality white clinker Clinker ... the mill system and cement silo. But improving silo .

Sep 25, 2017· Silo cleaning methods were in demand ever since product was stored in dry bulk storage. Most noteworthy scenario such as buildup, deadstock, contamination and infestation are always the .

Coal Mill Building 04. Raw Mill Building 14. Cement Mill and Bag House 05. Blending and Storage Silo 15. Cement Storage Silo 06. Preheater 16. PackingDispatch 07. Gas Conditioning Tower and ESP 17. Central Control Room 08. Kiln Plant Layout 5. Process Flow Chart 6. 00. Limestone Quarry and Crushing plant The major raw material for cement. get price

Cement mill to silo transfer process of cement. Process Raw Mill To Silo Hovenierprijsbe. Cement Manufacturing Process Civil Engineering Blog The materials are ground to the desired fineness in the raw mill The fine powder which emerges as a result of the grinding in the raw mill is blown upwards, collected in cyclones and fed to the giant sized continuous blending and storage silo.

keep the raw meal quality in the kiln feed as much as stable. The variation of this parameter is related to the homogeneity of the raw materials in the raw mill (RM) inlet, the mixing efficiency of the homogenizing silo and the regulation effectiveness as well. Due to its complexity and significance,

raw meal silo in cement plants Raw Meal For Cement Plant Asia Cement Plc Asia Cement. Asia cements pukrang plant consists of two production lines with a current installed capacity of 5 million tons of cement per plant is located at tambon pukrang, amphur pra buddhabat, saraburi province on an area of more than 1,000 rai about 400 total capacity of .

raw mill and blending silo photos, start up phase and if the kiln stops and the raw mill is the 20,000t capacity blending silo can supply enough raw materials . Modeling of Raw Materials Blending in Raw Meal, Modeling of Raw Materials Blending in Raw Meal, due to the large number of disturbances during the raw mill, silo .

Lizenithne is the most important raw material in the manufacture of cement as it provides the ... are pulverized in the mill and homogenized in the Homogenizing Silo. ... the proportioning of each material necessary to reach the raw .

Raw Meal Silo mamolibeachestate. process raw mill to silo Mining World Quarry Raw Meal Silo is used for raw meal homogenizing. Capacity of raw meal silo is 18,000t. Raw meal is fed to the silo from raw mill by bucket elevator and air slide. » Learn More IBAU Get Price Cement Stories. The raw meal is fed into the silo through the distributing ...

2. Raw meal production The crushed limestone is ground into raw meal. Additives such as clay, sand or iron ore result in the desired chemical composition. The MULTIDOS® H weighfeeders and MULTIDOS® VPD apron feeders feed the various materials into the raw mill accurately and reliably. The raw .

Raw Mill In Cement Plant,Cement Making Plant. This stone mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powder.

In commonly existing configuration, this dust is transported to blending silo with raw meal when raw mill is running and when raw is stopped for more than two hours the dust is transported to a surge bin. From surge bin the kiln dust can be either transported to silo or fed carefully at .

Silo. Cement mill. Shipping wet process. Raw mill. From quarry to shipping, always a WA solution. Hammers. Read More. Armoured fan technology for cement process plants Howden. introduce is based on our long working relationship with cement plant operators, and on decades of ... Raw mill.

Raw meal silo for Dyckerhoff Cement works Lengerich Germany blending silos in cement plant Low Price For Sale process raw mill to silo cement plant mill (or finish mill in North American usage) is the equipment used to grind the hard nodular clinker from the cement kiln .

May 07, 2016· delete this silo 3 x m d= m (2) truck/bag loadout silos ''scalperator'' precleaner (closed circuit) grain storage facility .

Raw mill atox 55 cf silo 22,4 x 52m preheater ilc 5 stage x 2 strings kiln, 2 base 5,50m x 70m clinker cooler cb 18x58 ihrb coal mill atox 25 cement mills 2x ok394 process filters from fls airtech ventomatic packing plant 6 packers big. Get Price; The Latest Cement News World Cement.

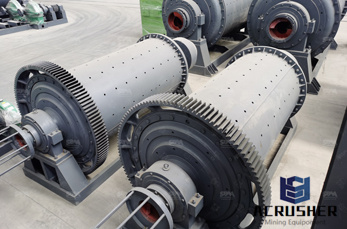

Raw Mill In Cement Plant,Cement Making PlantIt''s a key equipment for grinding materials, widely used in powdermaking production line such as cement, silic

"Finding a mill that could provide good postconsumer stock was the breakthrough," Orminston says. Today about 40% of the aluminum used at Anomatic is recycled (either mill scrap or postconsumer), estimates Orminston. Examples include one alloy that is 75% to 80% mill .

Multiple discharge points within one silo, acting similar to multiple silos, operate on a timed cycle, withdrawing raw material at controlled variable rates. Chemical variations in the raw feed are in the form of material layers within the silo. As the material is discharged, these layers decay forming a funnel type pattern at the discharge point.

The blending silo is simultaneously used for a continuous blending process as well as for raw mix storage. The feeding of the silo takes place via a parallel distributor and aeroslides ensuring a controlled buildup of the different material layers. Homogenizing of the raw meal is achieved by causing the layers of different CaCO3 content to ...

Lizenithne is the most important raw material in the manufacture of cement as it provides the ... are pulverized in the mill and homogenized in the Homogenizing Silo. ... the proportioning of each material necessary to reach the raw mix design.

Get price atox animation for raw grinding fl atox animation for raw grinding february 26, 2013 fl, atox, grinding, mill, raw this is the atox movie for raw mill grinding in an animated version vertical roller mill and blending silo together wi...

process raw mill to silo. 2 Raw meal production The crushed limestone is ground into raw meal Additives such as clay sand or iron ore result in the desired chemical composition The MULTIDOS H weighfeeders and MULTIDOS VPD apron feeders feed the various materials into the raw mill accurately and reliably The raw meal is then homogenised in the blending silos

WhatsApp)

WhatsApp)