9/Series CNC Grinder Operation and Programming Manual

Because of the variety of uses for the products described in this publication, those responsible for the application and use of this control equipment must satisfy themselves that all .

WhatsApp)

WhatsApp)

Because of the variety of uses for the products described in this publication, those responsible for the application and use of this control equipment must satisfy themselves that all .

Inefficient grinding operations hurt the bottom line. Learn how and where you can smooth out your grinding operation for maximum impact on time and materials. You may have heard something similar to this over the course of your machining and manufacturing life: Grinding .

Paving and Grinding Operations NS3 July 2012 California Stormwater BMP Handbook 1 of 5 Construction Description and Purpose . Prevent or reduce the discharge of pollutants from paving operations, using measures to prevent runon and runoff pollution, properly disposing of wastes, and training employees and subcontractors.

SPECIAL PROVISION/GUIDELINES FOR DIAMOND GRINDING AND HYDRODEMOLITION OPERATION SLURRY DISPOSAL, BENEFICIAL USE OR SOLID DISPOSAL AS BENEFICIAL FILL May 2, 2019 2 In addition, the HOS/DGS Management Plan must be reviewed and approved by NCDOT Resident Engineer or other designated person prior to the beginning of operations.

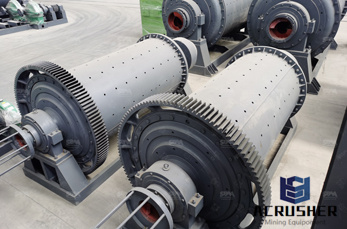

Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with...

Jul 28, 2008· Tips to optimize your grinding operation By Ana Elia Rocha McGuire on 7/1/2008 Particle reduction is the basic technology for producing many meat products. During the process of grinding meat, many factors affect quality and must be controlled. These factors include the quality of raw materials, temperature during processing and equipment ...

Dec 08, 2013· Types of grinding operation 1. Ruff or precision Grinding a) Snagging b) Offhand 2. Precision Grinding a) Surface grinding b) Cylindrical grinding c) Center less grinding d) Form and profile grinding e) Plunge cut grinding 5. Grinding Process Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. 6.

In this post, you learn the grinding machine and grinding machine operation, types of grinding wheel and more.. Grinding Machine. A grinder is commonly used to precisely shape and finish the given materials with low surface roughness and high surface quality.

A grinding wheel is an expendable wheel used for various grinding and abrasive machining operations. It is generally made from a matrix of coarse abrasive particles pressed and bonded together to form a solid, circular shape, various profiles and cross sections .

The grinding creates dust cloud and significant odor limiting neighbors'' ability to use their property and prohibiting children from playing outside during the grinding operation, which generally runs 2 weeks at a time, several times per year.

A process for the grinding of cellulose in which a raw cellulose material is uniformly moistened with a prescribed amount of liquid before the grinding operation wherein the raw cellulose material in the form of a cellulose web is fed continuously at a controllable constant speed to a grinding unit and the amount of liquid is so measured that the dry weight content of the moistened raw ...

Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started. Check the ore slot feeder for obstruction or hang—ups. Check the ball mill belt feeder for undue buildup of material. Check oil level in ball mill lube oil tanks. Also, check grease level in the mill ring gear spray lube drum.

SPECIAL PROVISION/GUIDELINES FOR DIAMOND GRINDING AND HYDRODEMOLITION OPERATION SLURRY DISPOSAL, BENEFICIAL USE OR SOLID DISPOSAL AS BENEFICIAL FILL May 2, 2019 2 In addition, the HOS/DGS Management Plan must be reviewed and approved by NCDOT Resident Engineer or other designated person prior to the beginning of operations. The

Grinding pressure: Grinding pressure is the rate of infeed used during a grinding operation; it affects the grade of wheel. A general rule to follow is that as grinding pressures increase harder .

Machining Operations. Machining operations are classified into 3 principle processes and they are turning, drilling and milling. There are other operations too that fall in miscellaneous categories such as boring, sawing, shaping, and broaching. A specific machine tool is required for taking care of each machining operation. Types of Machining ...

For surface grinding operations, the process parameters, the linear feed, the cross feed, and the depth of cut, have a direct influence on the roughness of the ground values of any of them would result in a higher material removal rate, and therefore, a .

offers 17,198 operation of grinding machine products. About 1% of these are vending machines, 1% are automatic door operators, and 1% are anesthesia equipments accessories. A wide variety of operation of grinding machine options are available to .

Mechanical Engineering Tutorials: 10 Short Answer Questions on Grinding Operation with Answers Testing and Balancing of Grinding Wheels, Internal centreless grinding.

Apr 06, 2015· Dry grinding – Dry grinding is the method of doing grinding operation without applying grinding produces undesirable effects on work surfaces. It leads to burring discoloration of work cutting edges of the grinding wheel lose their cutting capacity.

MACHINING OPERATIONS AND MACHINE TOOLS. 1. Turning and Related Operations. 2. Drilling and Related Operations. 3. Milling. 4. Machining Turning Centers. 5. Other Machining Operations ... – A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine) • Types

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Safety in grinding and cuttingoff operations with abrasive tools Preparation, mounting and operation of abrasive tool on machine should be performed in accordance with applicable instructions that include recommendations and requirements of: a manufacturer of grinding machine, manufacturer of grinding wheel, operation sheets for grinding operations.

OPERATOR''S MANUAL BENCH GRINDER Model BGH826 THANK YOU FOR BUYING A RYOBI BENCH GRINDER. Your new Bench Grinder has been engineered and manufactured to Ryobi''s high standards for dependability, ease of operation, and operator safety. Properly cared for, it will give you years of rugged, troublefree performance. SERVICE ONLINE GET PRICE

Optimize your surface grinding operations with expert tips on wheel grades, grit wheel sizes, cutting fluids, your grinding grip and grinding machine maintenance. Get the most out of your surface grinding operation with this detailed primer from a field expert.

WhatsApp)

WhatsApp)