: grinder wet

Multipurpose Electric Coffee Bean Grinder with 2 Removable Cups Premium Stainless Steel Mill Grinding Tool for Seeds, Spice, Herbs, Nuts Other Dry and Wet Ingredients | 200W Fast Grind .

WhatsApp)

WhatsApp)

Multipurpose Electric Coffee Bean Grinder with 2 Removable Cups Premium Stainless Steel Mill Grinding Tool for Seeds, Spice, Herbs, Nuts Other Dry and Wet Ingredients | 200W Fast Grind .

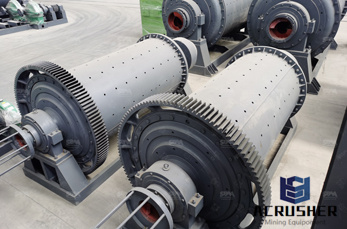

Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc. The applications of ball mills are ubiquitous in mineral

We cover the whole process chain of wet grinding and dispersing. Depending on your product and needs, we can design, plan and build your specific solution. Whether it is a single bead mill, an embedded system or a fullyautomated plant, we can provide the consistent, high quality you need, anywhere in the world.

This mill is not intended to grind wet grain. A rugged and durable mill, designed to last for generations. *Lifetime Warranty includes all parts, except the grinding plates which are a wear item. Grinding plate longevity will vary depending on usage, but you can expect them .

Discover the best Grain Mills in Best Sellers. Find the top 100 most popular items in Amazon Kitchen Dining Best Sellers.

The Population Balance Model, PBM, contains flaws making its use for effective simulation and control of milling circuits questionable. Presented is an analysis, based on published experimental wet grinding data, showing that the assumption of linearity, used in solving the PBM, is certainly wrong in many grinding mills and wrong for most commercial wet grinding circuits.

JXSC produce effective wet pan mills for various minerals processing plants. Wet pan mill is a kind of wet type grinding mill machine which widely applied in the grinding and selection circuit for ferrous metals, nonferrous metals, refractory and precious metals like gold and silver.

As stirred media mills are operated usually wet, the chapter focuses on wet grinding. Grinding and dispersing in stirred media mills is a process, which is widely used in different industries such as chemical, ceramic, pharmaceutical, filler, ink and cosmetic industry. Stirred media mills belong to the group of mills with free movable grinding ...

offers 1,596 wet grain mill products. About 37% of these are flour mill, 4% are grinding equipment, and 1% are coffee grinders. A wide variety of wet grain mill options are available to you, such as ball mill, end mill.

"stirred ball mill." There are quite a few types of Attritors; we can categorize them as dry grind Attritors, wet grind Attritors, regular speed Attritors, and high speed Attritors. A useful and simple equation describing the grinding momentum is M x V (mass x velocity), which enables us to see how the Attritor fits into the family of mills.

Bepex wet grinding machines are capable of handling the complete range of moisture levels. We have designed wet grinding mills to process vegetable and meat products, multiple wet and dry ingredients mixing, delumping and dissolving of fluids, slurries and pastes.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Wet milling, sorghumwhich has been con siderably modified from Jones'' original method, now consists of grinding the soaked grain and then separating the starch with water. Eleven companies were operating 14 wetmilling plants in 1950. They used about 6 percent of our corn crop, or 140 million bushels. Three of the plants have occasionally

Grinders are invaluable to craftsmen who work with wood, tiles or stone. To maintain safety and proper functionality, the grinding wheel must be kept balanced. A balancing arbor can be used to balance a grinding wheel. A balancing arbor uses a pair of collars between the grinding wheel .

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

Mill Type Overview. Three types of mill design are common. The Overflow Discharge mill is best suited for fine grinding to 75 – 106 microns.; The Diaphram or Grate Discharge mill keeps coarse particles within the mill for additional grinding and typically used for grinds to 150 – 250 microns.; The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges ...

Effect of Milling Environment on the Breakage Rates in Dry and Wet Grinding Abstract In ball milling the rates of breakage vary primarily with the size distribution of powder in the mill. Using an approximate solution to the batchgrinding equation, the acceleration and deceleration of breakage rates of all

Dry Grinding VS Wet Grinding. Previous Next ... Furthermore the throughput of a continuous feed mill is greater in wet grinding; probably due to the better flow properties of a pulp in comparison with a dry material. It appears, however, that the rate of ball and liner wear is greater in wet milling so the decision between wet and dry operation ...

Wet grinding ball mill in mining operation. Balls within mill retain their high grinding efficiency regardless of wear. Ball mills are used extensively for grinding metal bearing ores and abrasive minerals. When grinding ore prior to concentration, on the other hand, the grind is determined by the degree of reduction necessary to unlock the ...

83 Centrifugal force outward Fc mp 2 Dm 2 () is the angular velocity, mp is the mass of any particle (media or charge) in the mill and Dm is the diameter of the mill inside the liners. Gravitational force Fg mpg () The particle will remain against the wall if these two forces are in balance ie.

An Immersion Mill (a quantum improvement over traditional basket mills) combines mixing and milling achieving maximum particle size distribution, increasing production efficiency, and producing extraordinary quality and profitability. Immersion milling is a revolution in wet grinding dispersion technology that defies comparison.

Wet Grinding Mill. Introduction ELE Wet grinding Mill is mature technology, reliable and advanced processing. Include three types horizontal bead mill, Turbo type, Pin type, Disc type, suitable for different application and different viscosity.

Batch Ball Mill Grinding. Capacities and efficiencies in wet and dry ball milling at different speeds and ore charges have been discussed in the foregoing pages. The results are summarized in table 16, which shows that in both capacity and efficiency grinding was .

Corn wet milling and dry milling are the predominant methods of processing and each method produces distinct coproducts. The Corn WetMilling Process. The Corn wetmilling process is designed to extract the highest use and value from each component of the corn kernel. The process begins with the corn kernels being soaked in large tanks called ...

WhatsApp)

WhatsApp)