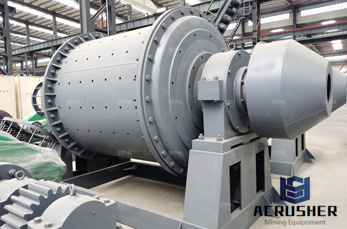

Raw Mill,Raw Mill In Cement Plant

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and .

WhatsApp)

WhatsApp)

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and .

Vertical Roller Mill is a new type advanced pulverizing equipment featuring good performance and drying function. Integrated with drying, pulverizing and powderselection, Vertical Roller Mill is widely applied in cement, chemical, coal and electric power industries.

monitoring of the mill process allows for Loesche is launching its new LMMaster for advanced vertical roller mill (VRM) control. This automation solution stabilises the VRM to allow operation with lower vibration. It also optimises mill performance by making accurate control actions several times .

LM series vertical roller mill is one advanced powder making mill which is developed through many years'' research experience and bringing in the latest mechanical techniques of Europe. It is one complete plant that integrated with drying, milling, classifier and elevator. It is the high standard mill with many advantages, like taking a ...

LM Vertical Roller Mill. LM vertical coal mill. LM Vertical slag mill. MTW European Trapezium Mill. MW Series Micro Powder Mill. Raymond Mill. TGM Super Pressure Trapezium Mill. LUM Series Superfine Vertical Roller Grinding Mill. T130X Superfine Grinding Mill. European Type Coarse Powder Mill. Straightthrough centrifugal mill.

LM Vertical Roller Mill. There are mainly three types in LM vertical grinding mill: the K series, the M series and the N series. Each type is suitable for different materials.

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

Jun 18, 2015· LM Series Vertical Grinding Mill ZENITH. LM Series Vertical Grinding Mill ZENITH. Skip navigation Sign in. Search. ... Ball Mill, Vertical Roller Mill) Duration: 5:16.

Vertical Roller Mill Working Principle. There are many different forms of vertical mill, but the working principle is basically the same. All these forms of vertical roller mill with the grinding roller (or the equivalent of grinding roller grinding parts), grinding roll along the horizontal circular motion on the disc, the vertical pressure exerted on the grinding roller through the outer ...

Vertical Roller Mill is a new type advanced pulverizing equipment featuring good performance and drying function. Integrated with drying, pulverizing and powderselection, Vertical Roller Mill is widely applied in cement, chemical, coal and electric power industries. It has become the mainstream equipment in the pulverizing industry.

LM Vertical Grinding Mills. LM Vertical Grinding Mills also called vertical roller mill, vertical roller mill is based on the principle of material bed comminution, the relative movement of the grinding roller and the grinding disc grinding materials, and by the hot air to ground material drying, with the grading device, in the grinding classification separator, coarse powder into the .

Because of increasingly mature vertical mill technologies and prominent technical advantages of vertical mills, SBM releases LM Series Vertical Mill. It is a vertical mill with multiple intellectual property rights and a successful result of absorption of foreign .

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology. It features in a combination of drying, grinding, classifying and conveying. HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, .

Our company''s vertical roller mill has two classic models, namely the LM vertical grinding mill and LUM ultrafine vertical roller mill, which is widely used in .

Vertical roller mill operation . Since the vertical roller mill tensioning device is packing system, oil tanks are not automatically inferior vena flow, after all the mill shut down or in the repair process, for the framework to enhance or decrease the pressure required to do the following:

LM vertical roller mill Benefits The whole plant is a vertical structure of strong systematic characteristic, so it occupies small area. From the crushing of raw material to grinding and packing is an independent production system. Get Price. Vertical Roller Mill, LM Vertical Roller Mill .

Jan 21, 2016· LM Vertical Roller Mill. LM vertical roller mill is our company in the relevant grinding technology is becoming more mature and technical advantages. Latest Solutions. Basalt Crushing Plant Jan 21,2016. Basalt has the advantages of high compressive strength, low crushing value, strong corrosion resistance, good adhesion and other advantages.

Vertical roller mill is used in cement raw meal grinding processing, cement clinker, slag and coal cinder. More. Sand Making Machine. Sand making machine is the most artificial system sand machine is universal, is efficient equipment with the world''s advanced level. ... LM Vertical Grinding Mill;

Jul 10, 2014· Cement raw material has been almost exclusively ground in roller mills (vertical airswept grinding mills) since the second half of the 20th Century. Loesche was .

LM Vertical Roller Mill LM series vertical milling machine, which is developed and launched by Zenith, sets medium crushing, drying, grinding, classifying and other functions as a whole, being the ideal equipment in the grinding industry.

Home → Products → Cement Plant Wear Parts → Vertical Roller Mill Wear Parts We offer a broad range of durable replacement parts for vertical roller mills. Replacement wear parts such as tires, grinding ring segments, armor rings and spindle shields are cast from our high chromium alloy irons and fully heat treated for optimum mechanical ...

3roller modular Loesche mill Type LM D in Kosice, Slovakia, 1991 The modular structure of larger roller grinding mills enables utilisation of the same components in different mill sizes. Module components include grinding rollers, rocker arms, pedestals and spring assemblies. The principle behind this structure was patented in 1970 and

Thailand: Siam Cement has ordered a LM +3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi. The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone. The cement producer previously ordered a LM +3 CS mill from Loesche for its Ta Luang cement plant in 2014.

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single ...

WhatsApp)

WhatsApp)