Coal Ash Management: Understanding Your Options Power ...

Mill Rejects. At most coalfired installations, mill rejects ("pyrites") are collected independently from the combustion residuals, but are often combined with the bottom ash in the sluice ...

WhatsApp)

WhatsApp)

Mill Rejects. At most coalfired installations, mill rejects ("pyrites") are collected independently from the combustion residuals, but are often combined with the bottom ash in the sluice ...

Closedloop combustion optimization at coalfired powerplant evaluated over two years. ... (SOFA) and five burner levels corresponding to five separate coal mills and five levels of fuel injection and combustion air (or fuel air — FA). In between each burner level, auxiliary air (AA) is injected. Above the highest fuel level, additional air ...

The paper presents a novel concept and method of coal combustion process analysis using flame scanners supervision system. The combustion process analysis and diagnostic has a crucial influence on boiler effectiveness, especially in high variance of load demand, which is nowadays a top challenge for coalfired power plants.

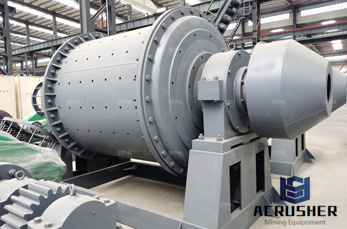

Combustion fundamentals, application – boiler perspective Combustion control, view point of boiler efficiency Blending of coal its impact on combustion optimization. Coal characteristics and impact on mill performance Milling system Bowl mill and tube mill basics and performance

Mercury Optimization Approach Humidification •Reduce Gas Temp. •Improve ESP Perf. •Increase Hg Capture Sorbent Injection •Injection System •Injection Lances •Multiple Sorbents Air Coal Mills APH Stack ESP Zonal Combustion Optimization •Combustion Sensors •Adj. Riffle Boxes

consulted the power plant Zhuhai on burning import coal, an optimization of the mill system in power plant Shajiao C was implemented, as well as exemplary optimization measures on the flue gas desulphurization system (FGD) in the power plant Shajiao A.

Coal and Combustion process 2. Boiler losses and efficiency 3. Combustion measurement and optimization ... Combustion optimization based on Diagnostic testing Date | Title of Presentation Page 35 The fuel lines balanced to each burner by ... Effects of burner tilt on combustion Results: • Coal mill .

The velocity signal is also critical to combustion optimization as it assists with proper primary airflow control, ideal flame stability, and avoidance of problems like coal layout, pipe fires ...

Based on Optimized Furnace Combustion Combustion Optimization is a prerequisite 1575 1675 1775 1875 1975 2075 2175 10 25 40 55 70 85 100 percent load(%) furnace exit gas temperature(°F) 2175 The FEGT should be on the curve PROVIDING that the mills, combustion airflows and burner belt performance is optimized.

A SUMMARY OF EXPERIENCES RELATED TO COMBUSTION OPTIMIZATION STEAG WORKSHOP=COMBUSTION ... To achieve optimum and efficient combustion of coal, equal ... • These systems utilize a pulverizer or mill to grind coal to a desired fineness and subsequently transport the coal to the burners using air as a transport medium .

This is all controlled by the coal mill or pulveriser, and its associated feeder equipment. Operation of the coal mill can affect the ramp rate of the power station and its ability to handle rapid changes in output. For coalfired power plants, the response time of the coal mills is critical for the overall reaction time to changing demand.

Optimization of Coal Blend proportions for sustained improvements in generation efficiency Arora CenPEEP NTPC LTD . ... – Care to be taken to avoid spontaneous combustion in stack yard – Control Mill inlet air temperature to maintain low mill outlet

Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an Improving Coal Pulverizer Performance and Reliability Coal Conveyer Coal Crusher Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor Coal Pulverizer Figure 1: Simplified diagram detailing a directfired coal burning system.

include maintenance status of the combustion equipment (burners, mills, and dampers), degree of process automation, operating practices, and limitations imposed by environmental regulations. Therefore, each combustion optimization project is very much sitespecific.

1. Optimize Power Plant Operations Primary Air Secondary Air Coal Coal Handling Mills Ash Ash Air Heater ESP ID Fans Steam Turbine ~ LP Feedwater Heaters HP Feedwater Heaters Coal quality and variability effects on boiler efficiency, availability, auxiliary power demand Fan and drive inefficiencies give high power consumption Feedwater heater ...

KEYWORDS: carbon in ash, LOI, combustion optimization, coal, boiler ABSTRACT Good combustion practices on coalfired boilers can reduce the daytoday variance and overall level of unburned carbon producing higher quality saleable ash as well as improved heat rate. Next to coal fineness, good combustion, characterized by good

coal mill and combustion operation for power plant. combustion optimization system under combined operation of coal mill A and coal mill C 3. 120 MW load, comparative test for the start and stop of the combustion optimization system under combined operation of coal mill A and coal mill .

Comprehensive approach to performance improvement and emissions reduction of a utility boiler, involving combustion tuning and combustion optimization, sootblowing optimization and removal of operating constraints, is needed to achieve best results. Combustion optimization of a pulverized coalfired boiler is a complex process, requiring in ...

Combustion Optimization to Improve Heat Rate and Lower NOx; ... It has a heating value of 6,600 Btu/lb. Coal mill pulverizers process and deliver fuel to the burners. Air adjustments are made ...

(3) As applicable, observe the damper operations as a function of mill and/or cyclone loadings, cyclone and pulverizer coal feeder loadings, or other pulverizer and coal mill performance parameters, making adjustments and effecting repair to dampers, controls, mills, pulverizers, cyclones, and sensors;

Minimum fly ash carbon content is achievable by implementing a comprehensive approach to combustion optimization. Actual values of carbon in ash or (Loss on Ignition) can vary widely, dependent on coal ash content, coal reactivity, coal volatile matter, boiler residence time and numerous boiler, as well as fuel burning equipment specifics.

Coal Crusher optimization for multiple styles of mills. We take pride in our coordinated approach of applying experience and first principles to properly balance and set up coal mills.

Coal Characteristics, Blending Mill Performance and Combustion Optimization from 25th Feb. to 27th Feb. 2015 PROGRAMME OVERVIEW Milling system performance has a vital role to play in efficient combustion process. It is also important for practicing power engineers to have a good understanding

itself to changing process situations like e. g. changes in coal qualities, mill wear, wall slagging, soot blowing etc. ensures compliance with the limit values for NO x and ammonia slip in all load cases (10 percent 100 percent). The combination of primary NO x reduction with advanced combustion optimization plus OnlineCFD as

WhatsApp)

WhatsApp)