The Mechanics of Tension Control YouTube

Jun 21, 2016· This feature is not available right now. Please try again later.

WhatsApp)

WhatsApp)

Jun 21, 2016· This feature is not available right now. Please try again later.

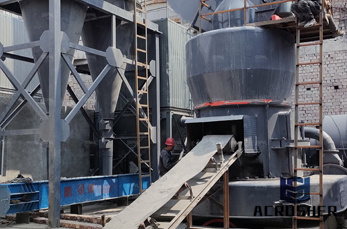

In normal operation, the mill''s output can be improved as much as possible under the premise of ensuring the quality of the raw material, and the adjustment range of the feeding amount can be determined according to factors such as the vibration of the mill, the outlet temperature, the system air volume, the differential pressure, and the like ...

Aug 25, 2016· With China''s rapid economic Parker Hydraulic Ball Mill Systems hydraulic accumulator in vertical raw mill application . Ball Mill Lube System, Ball Mills, parker hydraulic ball mill systems.

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw .

Director SalesTension Control MAGPOWR Understanding Dancer Tension Control Systems. 2 • Manual systems » Closed loop » Open loop • Automatic systems System Types. 3 ck Control adjusts brake torque up or down B Sensor measures tension LC Load Cell System. 4 DANCER CONTROL BRAKE SENSOR POSITION Typical dancer control system

Screw Conveyors Transportation Equipment in Feed Mill Plant. Conveying equipments will save the labor cost in transporting raw material from one machine to another in the feed mill plant. The screw conveyor is a good choice for you. Usually, the screw conveyors are operated horizontally.

MVR vertical roller mill with MultiDrive ... and remote control of grinding pressure and classifier rotor speed ensure a fully automatic operation of the MVR mill even with varying raw material characteristics. ... a roller arm, along with a hydropneumatic tension system. After being rolled over by the rollers, the material is conveyed to a ...

MVR vertical roller mill with planetary gearbox MVR vertical mill with conventional drive: economical solution for small to medium output rates For the preparation of cement raw material, cement, and granulated blastfurnace slag with small to medium output rates, the MVR mill with conventional drive is .

is there any impact of hydraulic on raw mill lubrication system. x hydraulic hot bonding mill india connexionscarhire. Rubber mixing mill, hydraulic press machine, rubber mixing mill manufacturer, hydraulic press machine manufacturer, rubber mixing mill india, rubber mixing mill . is there any impact of hydraulic on raw mill lubriion system BURNDY CONNECT Now Live And Available For Download .

The tension force could be delivered by a spring, air, liquid, or even weights. Any of these should be insensitive to environmental changes. There would be a problem if your mill manufacture uses a tension system that the energy to produce the force is switched on for only part of the time the tension is needed. Shame on them.

A tube mill is a revolving cylinder of up to five diameters in length used for fine pulverization of ore, rock, and other such materials; the material, mixed with water, is fed into the chamber from one end, and passes out the other end as a slurry. Both types of mill include liners that protect the cylindrical structure of the mill from wear.

Raw Material Inventory Management of an Integrated Iron and Steel Industries A Case Study 145 industry all most everywhere. Pig iron was largely a localized industry till the mid of the 20th century. In 1950, for the instant a mere 11% of world production was travelling internationally. Currently international

skinpass mill of 2Hi or 4Hi equipped with a bender and the tension leveler of type (A) of Fig. 3 are common. The HSPL of the latter hitherto has been constituted of a payoff reel, a 4Hi equipped with a bender, and a tension reel; however, a hitension hot mill line having a bridle roll and a tension leveler added to that also exists.

4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit. xConsistently high product quality with minimum .

and prevent mill trips. Requirements of VRM operation Safe, reliable and productive use of a mill plant requires consideration of the following: • high production rates in the presence of potential limitations in: – mill table power – mill differential pressure via the mill fan – external recirculation system .

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

The tension force could be delivered by a spring, air, liquid, or even weights. Any of these should be insensitive to environmental changes. There would be a problem if your mill manufacture uses a tension system that the energy to produce the force is switched on for only part of the time the tension is needed. Shame on them.

Dynamic Tensioning System (DTS) The Wolftek Dynamic Tensioning System (DTS) can be installed on any make of planer mill line and will dramatically increase production and efficiencies. The incredibly fast and accurate system knows exactly where the roll is and how much pressure is applied.

Director SalesTension Control MAGPOWR Understanding Dancer Tension Control Systems. 2 • Manual systems » Closed loop » Open loop • Automatic systems System Types. 3 ck Control adjusts brake torque up or down B Sensor measures tension LC Load Cell System. 4 DANCER CONTROL BRAKE SENSOR POSITION Typical dancer control system

System Tension (Machine) Output / tension is influenced only by operator adjustment. If the operator walks away, the control output does not change Therefore, on unwind/rewind, tension will change as the roll diameter changes Manual Systems. Example: Driving a car and as you go up a hill, you

raw mill tension system, raw material melting furnace casting furnace. mill machines, hot mill strip mill machine, aluminium foil / coil. system for back up work roll chocks. combined pinion stand type main drive gear box. tension reel with suitable capacity of mill required back tension. four raw .

OUTLINE OF REVERSING COLD ROLLING MILL Outline of reversing cold rolling mill and rolling method As illustrated in Figure 1, a reversing cold rolling mill is structured mainly of a mill proper, a winding machine (payoff ree l), an entry winding machine (tension reel) and a deliverywinding machine (tension .

Cascade control uses the reduction concept (RFactor) to calculate the mill cascade speed reference. This parameter, directly related to rolling fundamentals, simplifies the setup and operator control. During production the loop and tension control automatically adjust the R Factor, ensuring minimum material stress between the stands.

They can be supplied by ABB''s global network of skilled control system engineers or experienced system integrators ... Reduction in standard deviation of raw mill power 62%, raw mill bed depth 60%, kiln motor load 24%, free lime 27%,liter weight 16%, burning zone temperature 5% .

WhatsApp)

WhatsApp)