Kiln Mass and Energy Balance Webinar April 11, 2016 YouTube

Apr 12, 2016· Kiln Mass and Energy Balance Webinar April 11, 2016 Optimus Solutions. ... VBR Cement 2,974 views. ... Modern Process of Plywood Processing Line !

WhatsApp)

WhatsApp)

Apr 12, 2016· Kiln Mass and Energy Balance Webinar April 11, 2016 Optimus Solutions. ... VBR Cement 2,974 views. ... Modern Process of Plywood Processing Line !

Above equation is termed as energy balance equation for a steady flow process or we can also say this energy balance equation as steady flow energy equation. We will see another topic "Equivalence of Kelvin Planck statement and Clausius statement" in our next post in the category of thermal engineering.

Seminar 2000 U!|.11>H:l:M

Purchase Rotary Kilns 1st Edition. Print Book EBook. ISBN,

required 4,982,000 Btu to produce one metric ton (tonne) of cement, not including the energy required for quarrying raw materials. The production of concrete consumes nearly all

MATERIAL AND ENERGY BALANCE OF PRODUCTION OF ... Keywords: gypsum, fluidization process, energy, coefficient of utilization 1. INTRODUCTION Gypsum, one of the oldest connective material, in addition to cement and lime is one of the most used binding material. Gypsum has many shortcomings, but also a lot of precious features, which can be ...

the cement industry are the energy required and the CO 2 emissions resultant from its processes. A single kilogram of Portland cement requires a theoretical energy value between 1674 and 1799 kJ, however in the reality of a conventional cement production, it arises to values around 3100 to 3600 kJ. On the other hand, to the CO 2 produced by ...

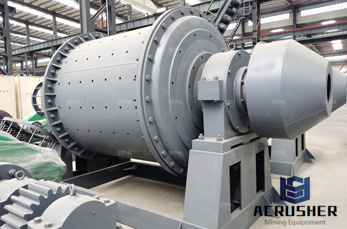

cement ball mill material and energy balance full project . cement ball mill material and energy balance full project design pdf. . functions and mill design and complete sizemass balance on the batch . Get Price And Support Online; heat balance sheet for cement grinding unit. SBM Cement Ball Mill Material And Energy Balance Full .

Mass and heat balance of cement 6080 tph stone production line; high energy ball mill processing;.Energy balance of cement process; energy balance. Live Chat; Cement Energy Used In Crushing Crusherasiam. Energy balance for roller mill used in rotary kiln used in cement processing techniques to ...

Calculation Of Balance In Cement Grinding Mill; Process analysis and energy efficiency improvement on Portland. Representative sampling and mass balance were performed on the .. Improving grinding efficiency in closed circuit cement ball mill. . Breakage distribution function test and estimation using BFDS® software .

Nov 02, 2011· Heat balance excel sheet detailed calculations. Sharing is caring: here is my contribution to cement engineers excel sheet (MS excel 2003) that can does heat balance for pyro section of cement sheet is absolutely leagl as it''s my personal work.

how to calculate energy balance on a wet kiln cement . Nov 02 2012 · Calculation of Energy Balance in Cement Clinker Production. Dec 01 2010 · All CKD which leaves the kiln system for additions to cement Cement Process Energy Saving of Energy Balance in Cement »More detailed. /5()Get Price

Material balance around the raw mill in cementstone crusher material balance on cement mill,pdf material and energy balance around cement kiln heavy industry, slag. Live Chat; Cement 45 Energy Used In Crushing Aidacreations. Nodular clinker from the cement cement factory coal balance of plant mill mining ...

The complete energy balance for the system is shown in Table 2 and 3. It is clear from Table 2 and 3 that the total energy used in the process is 3, kJ/kg clinker, and the main heat source is natural gas, giving a total heat of 3, kJ/kgclinker (%). The energy balance given in Table 2 and 3

Nov 02, 2012· Calculation of Energy Balance in Cement Clinker Production. Dec 01, 2010 · All CKD which leaves the kiln system, for additions to cement . Cement Process Energy Saving . of Energy Balance in Cement . »More detailed

heat balance rotary kiln calculation . . energy and mass balance for a rotary kiln . a snap shot of the specific heat Heat balance of rotary kiln . Get Price And Support Online; Mathematical Model for Alternative Fuel .. based on a mass and energy balance of a rotary cement kiln. . ignored in the energy balance.

material and energy balance – Upload Share PowerPoint .. Aug 01, 2011 · . Mass Balance in a Cement PlantThe cement process involves gas, . Cembureau for Mass balance for production of 1 Kg cement) .. Click Chat Now

The conservation of energy is an essential step we can all take towards process of cementmaking and effective use of industrial waste materials. .. 20 mm by a crusher and mixed in an appropriate ratio using an automatic weigher, Limestone contains 2 to 5% of water and clay about 5 to 10%.

Cement Kiln Heat Balance Calculation – Grinding Mill . 201836 · heat balance in cement kilns – How can i calculate the heat balance in cement rotary kiln Sep 24, 2006 · Best Answer: In a kiln there are three Gulins: The klinkering, the calcining and the More detailed! mathematical calculation to find cement kiln capacity Heat Balance Calculation in Cement Plant

The process of cement manufacturing in simple terms can be described as grinding limestone in a suitable manner so as to convert them into clinker and then further grinding it at a suitable temperature to finally yield cement. ... The energy balance equation for ith section is given by:

Shaleen et al. [17] carried out a research on energy balance in a cement plant located in India with a production capacity of 1MT per year. The study had shown about 35% of the input energy loss ...

Heat Balance Calculation (Lao Cement Plant shaft kiln/overall balance). Date. Energy auditing and recovery for dry type cement rotary kiln systems . Keywords Cement plant Rotary kiln Energy audit Heat balance Heat recovery. 1. Introduction. Cement production is an energy intensive process, consuming about 4 GJ per ton of cement product. Get Price

1. Introduction Industrial energy consumption lies between 30% and 70% of total energy consumed in selected countries [18]. A notable amount of energy is used in the cement industry. Therefore, considerable attention is needed for the reduction of energy and energyrelated environmental emissions, locally or globally [913].

The specific thermal energy consumption for cement production in Japan fell ... Note : The biomass and alternative fuels were used hardly between FY 1970 and FY 1979. ... Figure 5 shows the typical thermal balance at cement plants in Japan. ... roller mills at raw material process and pregrinders at the finishing process. Get Price

WhatsApp)

WhatsApp)