Roller Press in JSW Cement Vijaynagar YouTube

Mar 20, 2017· This feature is not available right now. Please try again later.

WhatsApp)

WhatsApp)

Mar 20, 2017· This feature is not available right now. Please try again later.

uses the testroller mill Atrol (throughput approx. 240 kg/h) for grindability testing and quantitative prediction of wear in industrial mills. Roller mill for granulated blast furnace slag grinding in China. Roller mill for cement raw material grinding in China. Roller mill for cement clinker grinding in Mexico. Coal grinding plant in Poland.

roller press at cement mill manual roller press at cement mill manual gigsghorg. basis of selection of a coal mill in cement industri Cement millWikipedia A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.

CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS. energy of a cement plant. Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press.

FLSKoppern roller press In the traditional cement grinding installation, clinker of a maximum size of about 1″ is being fed to a ball mill for grinding in 2 or 3 compartments with grinding media ranging in size from 3½ to 4″ down to about ½".

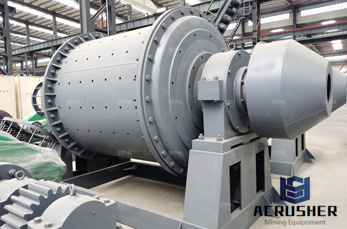

Roller Press. is a professional mining equipment manufacturer. The roller press is used for grinding fragile materials such as cement clinker, granulated blast furnace slag, raw materials for cement (limestone, sandstone, shale, etc.), quartz sand, iron stone, etc.

May 18, 2017· At the beginning of the 1980''s, KHD became one of the first companies to implement the industrial roller press as new grinding technology. Since then, KHD has sold over 300 roller presses, and ...

The new semifinish grinding system, equipped with KHD roller press technology, will be erected at SANKO Bartin Cement´s new 3000 t/d cement production plant in Bartin in the Black Sea region of Turkey. A roller press/Vseparator circuit will be installed in semifinish mode in front of two ball mill systems with dynamic separators.

Roller Press . Hai friends, Our cement grinding is the combination of "Roller Press and Single Chamber ball mill. . My question is "Are there any cement plants which grind both slag and clinker simultaneously in the roller press" and if so what are the type of problems are you facing.

• Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this paper authors are covering the process diagnostic study of Ball mill for cement grinding. 2.

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of .

Aug 13, 2018· Maintenance in a cement factory. Their cement grinding roller press, consisting of two rollers, needed maintenance. After 3 years of operation the old rollers needed to be replaced with a new set.

Tube mills are often the most important part of the combined grinding system. How to play the potential of the tube mill is the goal that every cement worker is striving for. The internal structure design of the original tube mill has far exceeded the requirements of the process parameters of the tube mill in the current combined grinding process system engineering.

The KHD Humboldt Wedag Roller Press is available in eight standard sizes ranging in grinding force from 2 to 20 meganewtons. KHD Roller Presses offer a reliable solution for every application for grinding cement, slag, raw material or for special applications, such as preparation of ore.

Leejun roller press for cement grinding Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Leejun roller press for cement grinding, quarry, aggregate, and different kinds of .

mill competently or in partial. Roller press is characterized by low power consumption and lower noise for reforming old factories Hydraulic Roller Press at site Construction of Hydraulic Roller Press The hydraulic roller press consists of a frame assembly in which two rotating rollers are mounted with roller bearings and bearing housings.

Operating principle of Hydraulic Roller Press . The feed material (cement clinker, slag or other cement raw material) is supplied to the roller press through inlet and here it is directed down between the two rollers which rotate against each other. At the same time, the movable roller is forced towards stationary roller at a fixed hydraulic ...

the cement and minerals industry. Always up to expectations. The KHD Humboldt Wedag Roller Press is available in ten standard sizes ranging in grinding force from 2 to 32 meganewtons. The specific grinding pressure is kept below N/mm 2 in order to limit the stress on the rollers (grinding pressure = grinding force/roll diameter/roll width ...

Foundation for roller press in a cement plant A case study Buch The paper describes roller press structure in a cement mill of a cement plant. When provision of press is planned along with mill building, it is possible to provide suitable structural arrangement. .

the cement and minerals industry. Always up to expectations. The KHD Humboldt Wedag Roller Press is available in ten standard sizes ranging in grinding force from 2 to 32 meganewtons. The specific grinding pressure is kept below N/mm 2 in order to limit the stress on the rollers (grinding pressure = grinding force/roll diameter/roll width ...

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement mill Wikipedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Roller Press, Roll Squeezer HAIJIAN. The roller press is a new type energy saving cement grinding equipment developed in the mid 1980s. It can completely or partially replace the ball mill that is highly energy consuming.

The ball mill process scheme of cement ball mill and roller press is a mature process system at present, which can meet the basic needs of grinding process to the greatest extent. After the combined cement grinding system of ball mill and roller press is put into production, the output of the system is low, and the energy consumption ...

WhatsApp)

WhatsApp)